PLASTICS

Plastic

is a generic term used to cover a broad range of materials, including polymers,

resins and composites that can be formed into shapes by various manufacturing

processes.

Plastic

is a generic term used to cover a broad range of materials, including polymers,

resins and composites that can be formed into shapes by various manufacturing

processes.

Custom components can be manufactured to meet your requirements using new or existing molds or dies. In addition to part and tooling design, prototyping, bridge tooling and production, we can help you determine the manufacturing method appropriate for your specific needs.

A&T also provides many value-added services to complement our manufacturing capabilities. These services include inventory and logistics management, machining, painting, and subassemblies of plastic and/or metal components. An additional enhancement to your inventory and purchasing options is our ability to provide solutions for the supply of low-volume, complex or large parts.

Manufacturing Methods

Injection Molding: Most common method for producing plastic parts, especially very small parts.

Extrusion: Used for plastic tubing, pipe and shapes.

Vacuum Forming: Commonly used with disposable thin-wall packaging.

Thermo Forming: Normally used for short production runs of large-scale parts.

Blow Molding: Typically used to make bottles and hollow containers, 1 oz to 10 gallon.

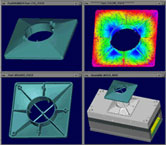

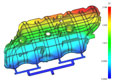

Tooling

- Plastic Injection Molds

- RIM Molds

- Blow Molds

- Extrusion Dies

- Gauges

- Fixtures

Other Services and Products

The ability to manufacture custom cables and wiring harnesses using a wide array of standard connectors is an important segment of our product offering. We can provide an off-the-shelf sample or create a functional prototype for testing and evaluation.

A&T

can guide you in the conversion of metal parts to plastic, which can be cost

effective, save production time and decrease the weight of the component. Parts

that are not good candidates for conversion can still benefit from prototyping

in plastic by reducing the time required to verify design criteria.

A&T

can guide you in the conversion of metal parts to plastic, which can be cost

effective, save production time and decrease the weight of the component. Parts

that are not good candidates for conversion can still benefit from prototyping

in plastic by reducing the time required to verify design criteria.

In conjunction with manufacturing parts that meet the stringent requirements of our internal quality system, we can readily produce parts to established electrical, medical, military and government specifications and ratings. Depending on the product application, parts can be produced in a clean room environment or undergo a sterilization process.