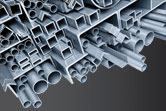

Extrusions

Extrusion is the process of shaping a material in a closed cavity by forcing it through a shaped die using either a mechanical or hydraulic press. The extrusion process can be performed hot, warm or cold depending on the type of material and the desired outcome. Although aluminum is the most commonly extruded material, this process can be used for a large variety of other metals as well as many plastics and ceramics.

Extrusion is the process of shaping a material in a closed cavity by forcing it through a shaped die using either a mechanical or hydraulic press. The extrusion process can be performed hot, warm or cold depending on the type of material and the desired outcome. Although aluminum is the most commonly extruded material, this process can be used for a large variety of other metals as well as many plastics and ceramics.

Intricate cross sections and long continuous materials are ideal applications for extrusion. Significant benefits of extrusion include minimal need for secondary machining due to the creation of near-net shapes and the ability to withstand high deformation without tearing because no tensile stresses are introduced during the manufacturing process. A&T's extensive experience and consistent commitment to quality combine to ensure that your extruded parts will be manufactured using the appropriate method and delivered on time and error free.

Intricate cross sections and long continuous materials are ideal applications for extrusion. Significant benefits of extrusion include minimal need for secondary machining due to the creation of near-net shapes and the ability to withstand high deformation without tearing because no tensile stresses are introduced during the manufacturing process. A&T's extensive experience and consistent commitment to quality combine to ensure that your extruded parts will be manufactured using the appropriate method and delivered on time and error free.